Twin House Houtigehage

home extension

The Twinhouse

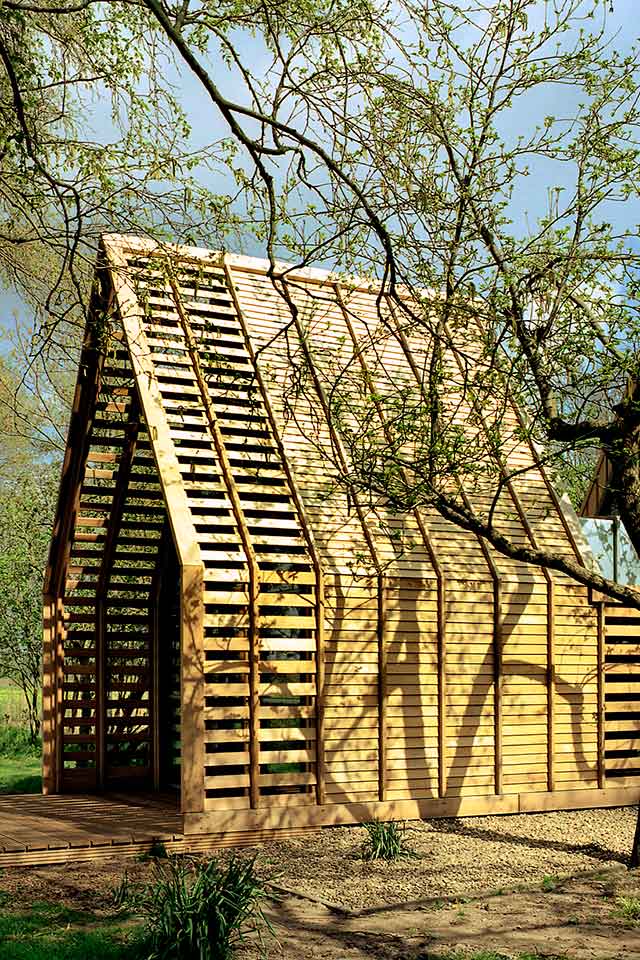

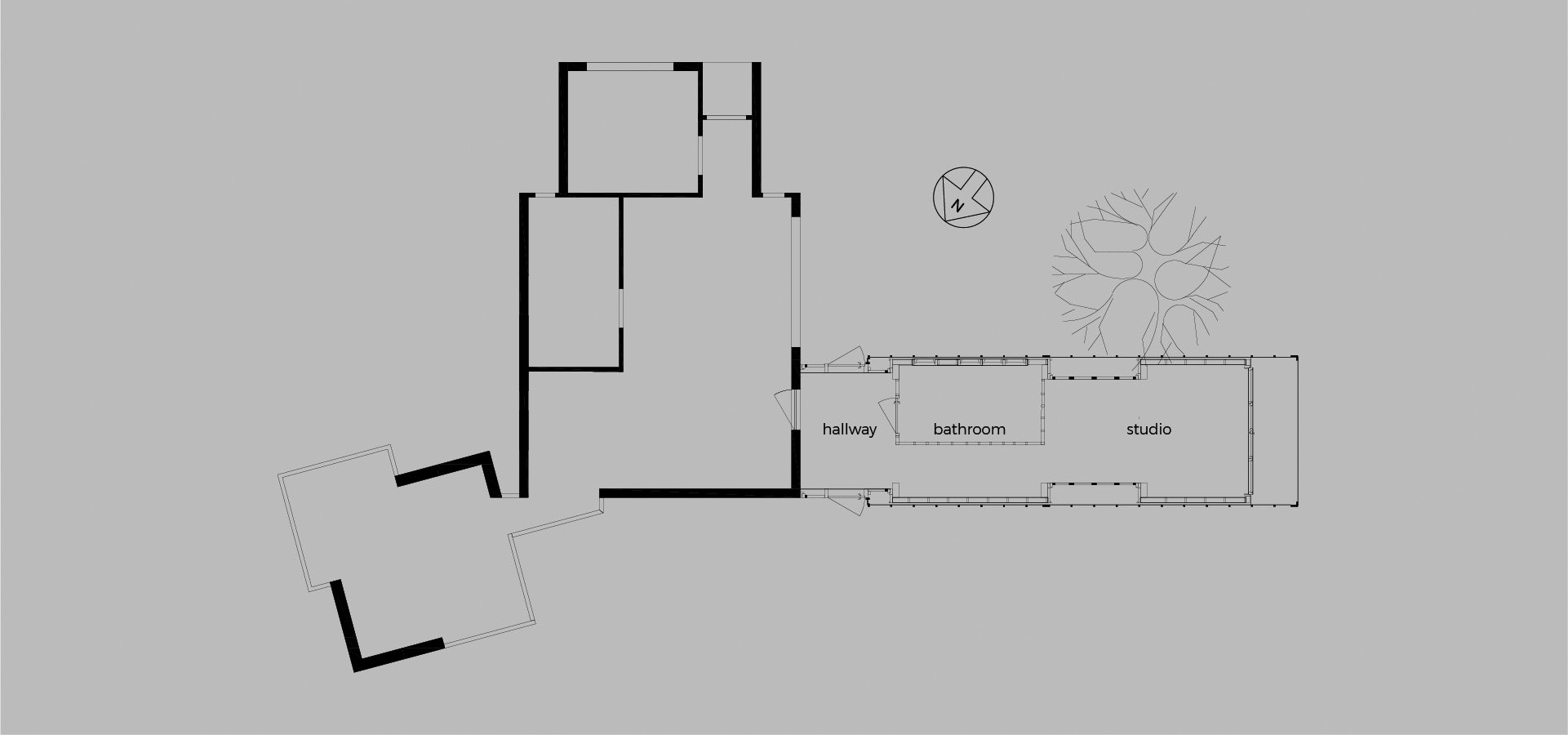

On an estate located in the upper north of the Netherlands a farm converted to a dwelling is situated together with a guesthouse, a barn and trough a glass hallway connected to the dwelling a kitchen. One extension is added, a studio. With this extension the story of the estate will be rewritten. An accidentally collection of small buildings changes into a constellation of typical houses. To tell this story the last extension should be more archetypical then the other buildings.

Material

Each of the other houses is characteristic by its own shape and material. The new extension adds a saddle roof as a shape and western red cedar as a material. Because the scale of the extension measures with the scale of the former farm the design exists of two of a kind archetypical houses. This way there is no competition between the extension and the farm and in addition the extension doubles its own statement.

Shape

The archetype is a builded cartoon. A fat outline describes the shape which is illustrated by a raster. The fat outline draws the shape of the two little houses. The fine bevel siding raster fills the surface, half open where daylight is desired. An inside shape connects the little houses in itself and with the main house. This part is covered with zinc. After a while the wood, the zinc, the thatched roof of the farm and the gravel around the house will become a palette of gray tints.

Cladding

To apply the red cedar bevel siding a special sawing plan was needed. Normally the wood cladding exists partly of plain sawn timber and partly of quarter sawn timber, also named mixed grain. Plain sawn timber with the nerve parallel to the surface of the roof is not applicable. The plain sawn timber will be stricken by the rain and the appearance of the cladding becomes irregular because of the variable direction of the wood nerve. In association with Assink Inc. an alternative sawing plan is developed which makes it possible to make all the bevel siding quarter sawn timber without loss of wood. Not only for the sustainability, but also for the appearance of the house, it is finely to give the entire bevel siding the same nerve direction.

Cladding, traditional bevel siding versus alternative bevel siding

For the façade and the roof is chosen to manufacture the red cedar in bevel siding. Horizontal timber which changes in thickness and using a rabbet to overlap each other. Applying bevel siding on a roof can be harmful for the roof for these parts which are plain sawn. The Nerve of the wood lies parallel to the surface of the roof. The rain coming from the roof affects the wood and after a while the bevel siding warps or distorts in other ways.

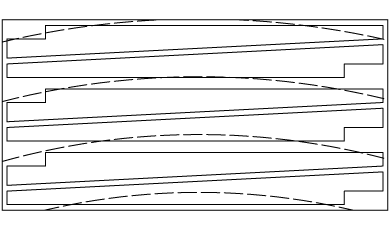

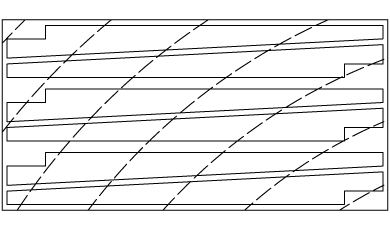

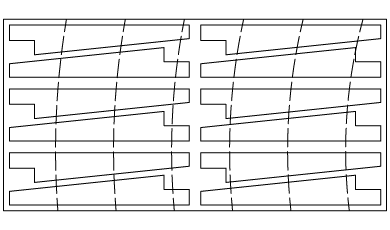

Quarter sawn timber does not have this problem. The nerve of the wood lies not parallel to the surface of the roof. Not only for the sustainability, but also for the appearance of the house, it is finely to give the entire bevel siding the same nerve direction. This results in less difference in color and structure between the bevel siding. The figures below showing the way the alternative sawing plan is build up versus the traditional sawing plan.

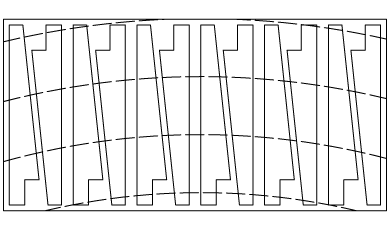

Traditional bevel siding

The bevel siding is sawn from rough beams measuring 10 X 20 cm. The direction of the nerve is different in each beam, dependent where they where cut out the trunk. Half off the bevel siding has nerves at right angles to the surface, the other half parallel to the surface. The last one, with the typical flamed look, is not applicable for roof cladding. The rain coming from the roof will loosen layers of the wood.

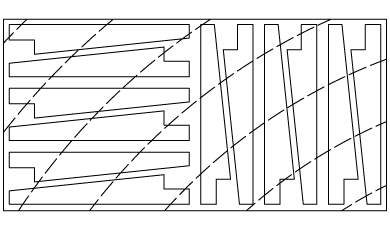

Alternative bevel siding

The smaller bevel siding can be cut out as well along the direction of the beams as at right angles to the beams. This way it is always possible to saw in the best direction compared to the nerve. The entire bevel siding is quarter sawn timber and has a wood nerve structure at right angles to the surface. This way it is applicable for roof cladding and the appearance is nicer than traditional bevel siding.

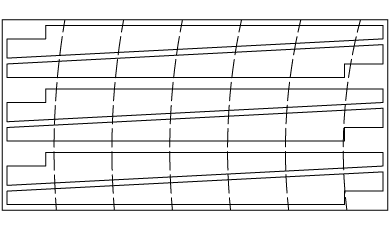

Rabbet

The rabbet is not made on the straight side of the bevel siding but at the slant side. The bevel siding is connected to the wall and roof back to front. This way the rough sawing side comes inside while the plane side comes outside.

Project data

Team: Bart Aptroot, Catarina Gonçalves, Joachim Karelse. Location: Houtigehage. Gross floor surface: 60 m2. Gross volume: 145 m3. Constructor: J. Koblens, Heerhugowaard. Advice: Assinkhout Inc., Neede. Workmanship: Workmanship by owner. Delivery: October 2004. Photography: Jim Ernst © Aerial photography: KAP service ©.